Wednesday 7 September 2016

Rolls-Royce struggles to improve returns on Dreamliner engines

Rolls-Royce is facing mounting costs relating to after-sales service contracts on its Trent 1000 engines. Three engines from the 50-strong Boeing 787 fleet of aircraft operated by Japan’s All Nippon Airways (ANA) have failed so far in 2016 and were found to contain turbine blade corrosion. In late August ANA made the decision to gradually replace turbine blades on all 100 installed engines on the 787 fleet over a period of three years, even though the problems appear to be associated with a limited section of the fleet.

ANA may consequently seek compensation from Rolls-Royce, who have already designed and have begun production of new replacement blades. Rising costs and possible compensation claims would threaten the already tight profit margins at the manufacturer. The Ishka View is that the cost of the ANA blade replacement process will impact the profitability of the Trent 1000 programme. However, as long as the premature blade corrosion remains localised (ANA’s higher rate of utilisation may be contributing to an accelerated degradation) it should avoid hurting sales for the Trent 1000-67 engines, or Rolls Royce’s ability to sell its newer engine variant, the Trent 1000 TEN.

ANA considers compensation as cancellation costs mount

The airline cancelled 18 flights last month and initially stated that it planned to cancel 300 flights in September. The cost of the first nine cancelled flights was estimated at 55 million yen ($532,000) by the airline which is considering compensation from Rolls-Royce, ANA sources told Reuters. A Rolls-Royce spokesman declined to comment to Ishka on the negotiations but speculation mounts that any compensation may take the form of discounted purchases and free parts, rather than cash.

So far corrosion has only been identified on three of ANA’s 787-8 engines.. Rolls-Royce says this relates to their “intensive” use. New replacement turbine blades are being developed by Rolls-Royce and will be available early in 2017, but refitting the entire fleet could take up to three years.

After stating that up to ten flights a day would be cancelled, ANA now intends to keep cancellations as close to zero as possible by using spare aircraft and Boeing 777 training aircraft. This should restrict the costs associated with the inspection of engines in the fleet and any compensation claim ANA makes to Rolls-Royce. Any further financial impact on the airline will be announced in October.

Rolls-Royce factors in £64m cost to aftersales contracts

In 2015, Rolls-Royce reduced its estimate on the future maintenance costs on Trent 1000 launch engines. Significantly, the manufacturer believed that the risk of higher costs had decreased over the year following better performance data on the engine and the first shop visits by customers. This resulted in a reversal of the previously recognised impairment, and a profit of £65 million.

However, Rolls-Royce abandoned its estimation when ANA first reported the engine trouble in March. In its first-half financial results the group announced a 5% underlying revenue reduction which was partly down to increased technical costs on the Trent 1000 engine, and reported £64 million in after-sales service costs. Rolls-Royce chief executive, Warren East said: “It is an issue, but it’s a manageable issue.”

Scenarios

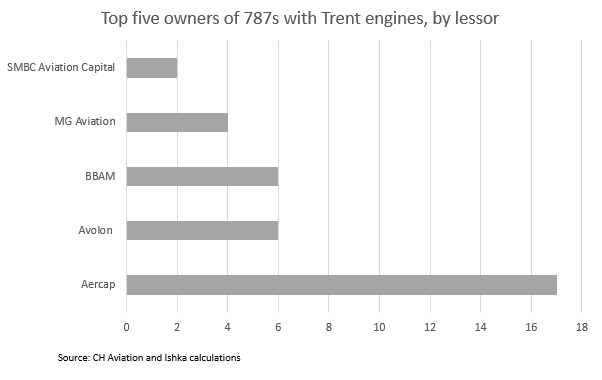

The Trent 1000 engine is also in use with Air New Zealand, British Airways, LATAM, Air China, and Scoot on their 787 fleets. Of the 445 Dreamliners currently in service, just under 40% are equipped with Trent 1000 engines. If the same corrosion issue was to arise with other carriers engines, then Rolls-Royce can expect their servicing costs to continue to rise. However, the problem may well be unique to the way ANA utilises its Dreamliner fleet. Like other operators in Japan, ANA uses some of its long-haul aircraft like the 787 on short-haul domestic routes due to their higher density capability. Rolls-Royce believes the corrosion is the result of this more intensive use by ANA. Ishka understands that other users of Trent 1000 engines will also have their turbines blades replaced on a rolling basis. Rolls-Royce spokesman, Richard Wray said: “the issue is being managed with other operators through ongoing maintenance.”

The Ishka View

The Trent 1000 engines remain fundamentally safe. Neither the Federal Aviation Administration or the European Aviation Safety Agency have taken any action although any troubles experienced by the largest operator of 787-8s is bound to grab the attention of other airlines and lessors who own or operate the engine.

Nonetheless the decision to inspect the whole 787 fleet is a heavy one that has potentially cost the airline more than $100,000 based on the figures released by ANA. It appears that the carrier initially overestimated the number of flights it would have to cancel and has reduced its estimate from 300 cancellations across September to close to zero. This will scale back the amount and type of compensation ANA will seek to claim.

The news comes at a difficult time for Rolls-Royce which reported an 80% fall in profit for the first half of 2016 and has issued five profit warnings in the past two years. It remains to be seen what compensation, if any, ANA will negotiate with the engine maker, although it is likely to hurt the profitability of the programme. Rolls-Royce will work hard to keep ANA happy, and itself out of the headlines, as it begins to ramp up its other engine programmes including the Trent 1000 TEN which is due to enter service in 2017 and the upgraded Trent XWB.

Sign in to post a comment. If you don't have an account register here.